European premiere at IAA Transportation: cellcentric gives exclusive insights into NextGen fuel cell system for sustainable heavy-duty transportation

- Virtual model shows the design of NextGen fuel cell system

- Important step towards CO2-neutral mobility in global road transportation

- Industrial-grade prototype production now in operation and preparation of large-scale series production of fuel cells towards the end of the decade is ongoing

- Pioneer in Europe with the aim of producing fuel cell systems on an industrial scale with a high level of vertical integration

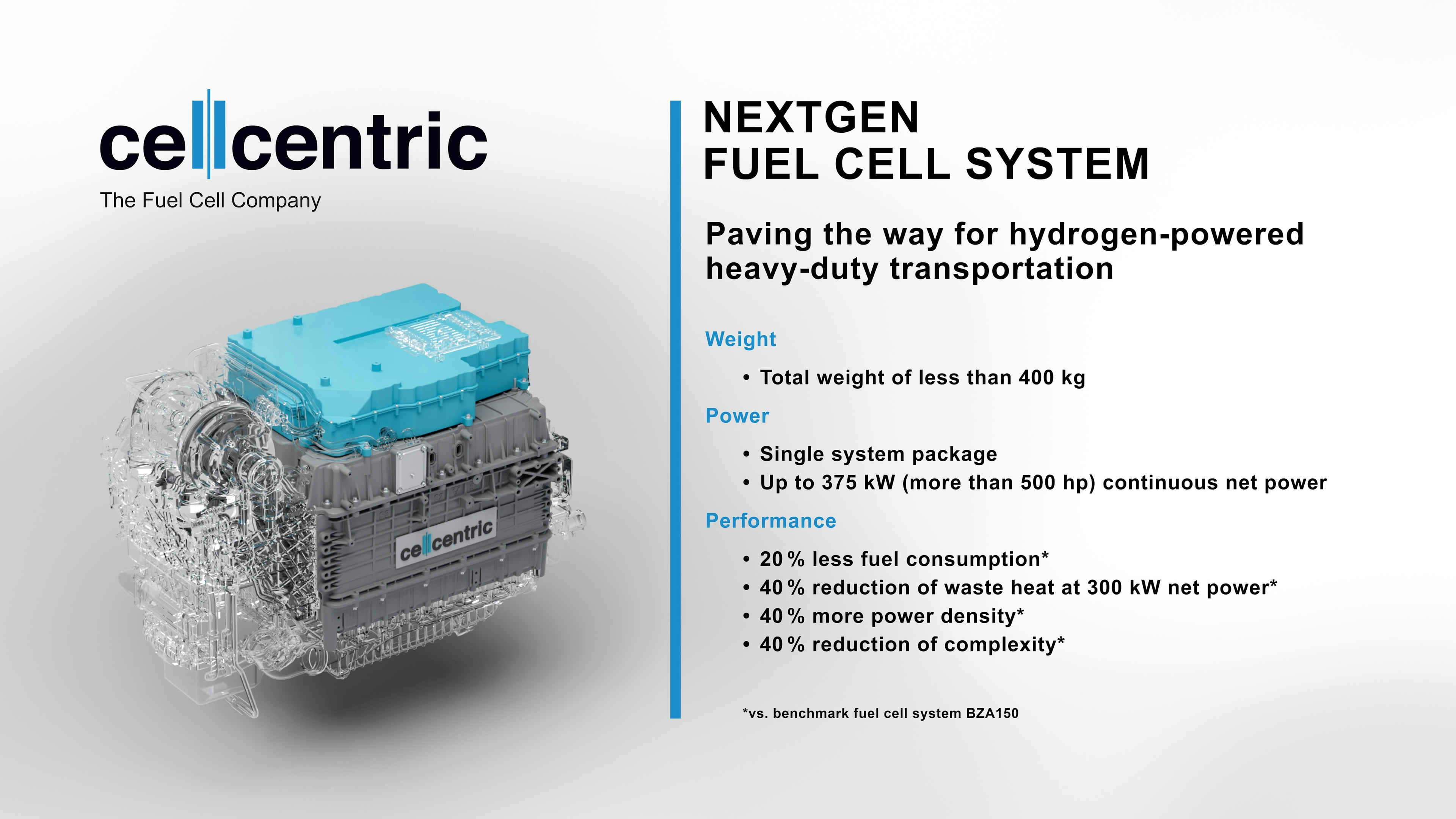

Esslingen/Hannover (Germany) – As a sustainable solution for CO2-neutral mobility in global road transportation, cellcentric will be presenting a virtual model of its NextGen fuel-cell system for long-haul heavy-duty transport for the first time at the IAA Transportation in Hanover, Germany from September 16 to 22 (Hall H24, booth C11). This virtual model provides a preview of the dimensions and design of the game changing new generation of fuel-cell systems. With a total weight of less than 400 kg, this new system is designed for conventional 13-liter diesel engine compartments. The new single-packaging fuel-cell system will combine high efficiency and performance with market leading TCO. In addition, the system is characterized by higher operating temperatures and lower cooling requirements*.

NextGen fuel cell system:

Target performance figures (*vs. benchmark fuel cell system BZA150)

- Single system package

- Up to 375 kW (more than 500 horsepower) continuous net power

- 20% less fuel consumption*

- 40% reduction of waste heat at 300 kW net power*

- 40% more power density*

- 40% reduction of complexity*

Start of ramp-up to highly efficient large-scale production

Current BZA150 production of fuel cell systems in Esslingen (Germany) is a milestone towards reaching CO2-neutral mobility in the heavy-duty transport of tomorrow, utilizing highly efficient industrial-grade production processes. Furthermore, the industrialized pilot production in Esslingen marks another step towards the arrival of Europe's largest fuel cell production facility – the new KLIMA|WERK factory in Weilheim – which is planned to open towards the end of the decade.

About cellcentric

cellcentric develops, produces, and markets fuel cell systems for use in heavy-duty commercial vehicles as the focus as well as offroad applications. cellcentric is a joint venture founded in 2021 between Daimler Truck AG and the Volvo Group. The company utilizes the know-how and extensive experience gained from decades of developing fuel cell systems by its predecessor companies. cellcentric’s goal is to become a leading global manufacturer of fuel cells and thus making a contribution to climate-neutral and sustainable transportation by 2050. More than 560 highly qualified employees are driving our state-of-the-art fuel cell technology forward. They work in interdisciplinary teams at our sites in Nabern, Stuttgart-Untertuerkheim, Esslingen (Germany) and Burnaby (Canada). Around 700 individual patents granted, underline the company’s leading role in technological development.

Press contact

+49 (0)175 5337198

christian.kleinert@cellcentric.net